Top Sealants Used in Construction & Their Key Functions

Top Sealants Sealants play a crucial role in construction, providing protection, flexibility, and durability to buildings and infrastructure. They help in sealing joints, preventing water infiltration, and enhancing structural integrity. Choosing the right sealant depends on the application, environmental factors, and material compatibility. Below are some of the most commonly used sealants in construction and their key functions.

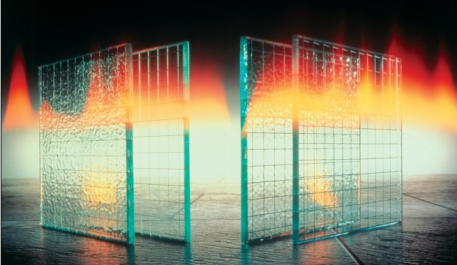

1. Silicone Sealants

Silicone sealants are widely used due to their flexibility and weather resistance. They are ideal for:

- Glass & Metal Joints: Ensures strong adhesion and long-lasting elasticity.

- Weatherproofing: Withstands extreme temperatures and UV exposure.

- Expansion Joints: Maintains flexibility even under structural movement.

2. Polyurethane Sealants

Polyurethane-based sealants are known for their strong adhesion and durability. They are commonly used in:

- Concrete Joints: Provides excellent bonding and crack resistance.

- Road & Bridge Construction: Withstands heavy loads and environmental stress.

- Wood & Metal Applications: Ensures long-term durability and moisture resistance.

3. Acrylic Sealants

Acrylic sealants are preferred for their ease of application and paintability. Their key applications include:

- Interior Joints: Ideal for sealing gaps in walls, ceilings, and doors.

- Masonry & Concrete: Offers good adhesion and resistance to weathering.

- Decorative Finishes: Can be painted over for aesthetic appeal.

4. Butyl Rubber Sealants

Butyl rubber sealants offer excellent waterproofing and adhesion, making them suitable for:

- Roofing & Flashing: Prevents water leaks and enhances durability.

- Gutters & Drainage Systems: Provides a strong, watertight seal.

- Glazing Applications: Ensures effective sealing in window and door installations.

5. Polysulfide Sealants

Polysulfide sealants are highly resistant to chemicals and extreme conditions, making them ideal for:

- Marine & Industrial Applications: Used in tanks, reservoirs, and fuel storage.

- Concrete Pavements & Runways: Withstands thermal expansion and heavy loads.

- Structural Joints: Provides long-term performance in demanding environments.

6. Hybrid Sealants (MS Polymer Sealants)

Hybrid sealants combine the best properties of silicone and polyurethane, offering superior adhesion and flexibility. They are widely used in:

- Multi-Purpose Applications: Suitable for wood, metal, concrete, and glass.

- Eco-Friendly Construction: Low VOC emissions and environmentally safe.

- High-Performance Bonding: Ensures long-term durability with excellent elasticity.

Choosing the Right Sealant for Your Project

Selecting the best sealant depends on factors such as:

- Environmental Conditions: Temperature variations, UV exposure, and humidity levels.

- Material Compatibility: Adhesion requirements for different construction materials.

- Movement & Flexibility Needs: Expansion and contraction of structures.

- Longevity & Maintenance: Durability and ease of repair over time.

Sealants are essential for ensuring the longevity and efficiency of construction projects. Understanding their properties and applications helps in choosing the right type for different structural needs. Whether it’s waterproofing, weatherproofing, or providing flexibility, the right sealant enhances the durability and performance of any building or infrastructure.

Stay updated with the latest industry trends for more construction insights and expert recommendations.